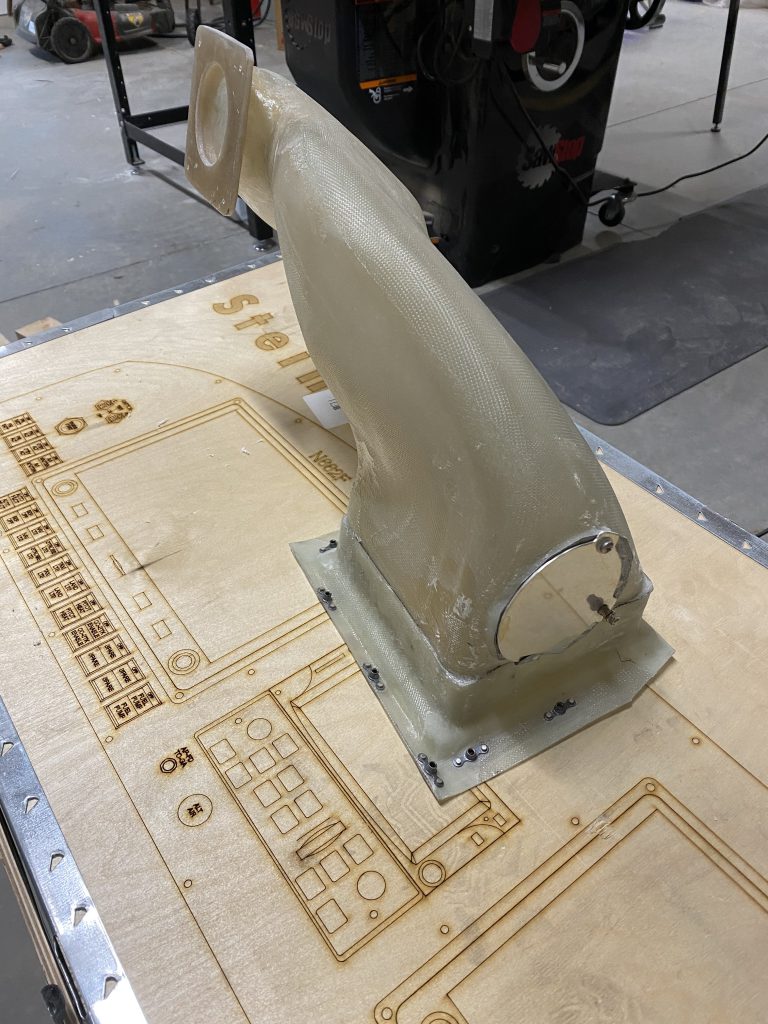

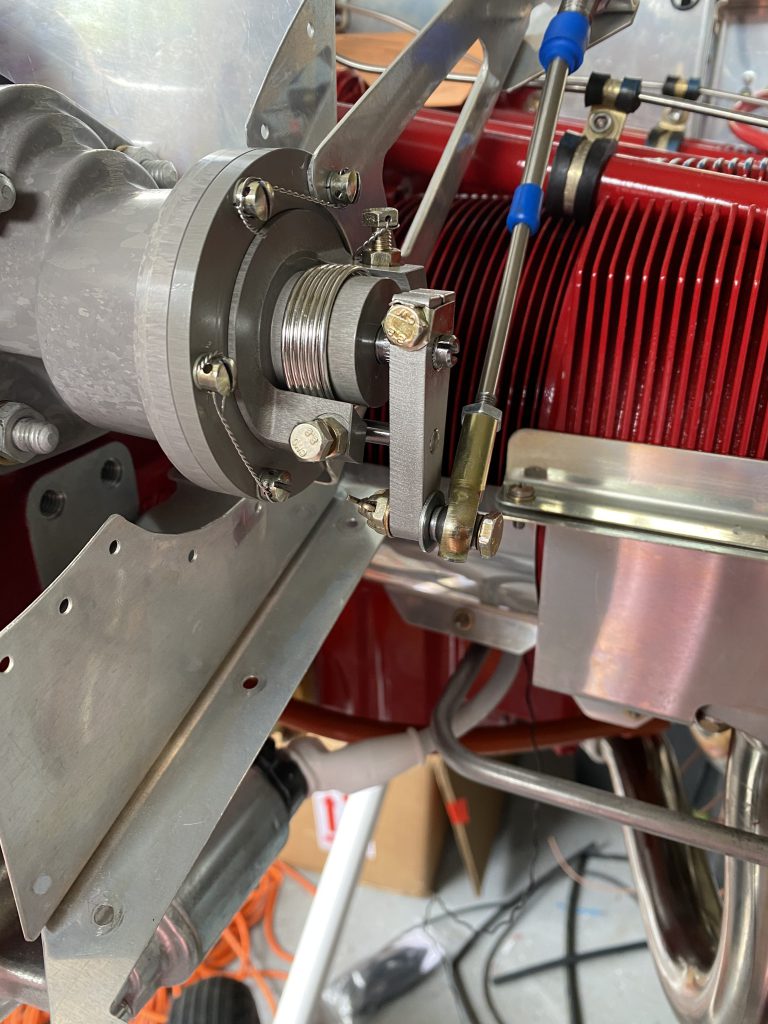

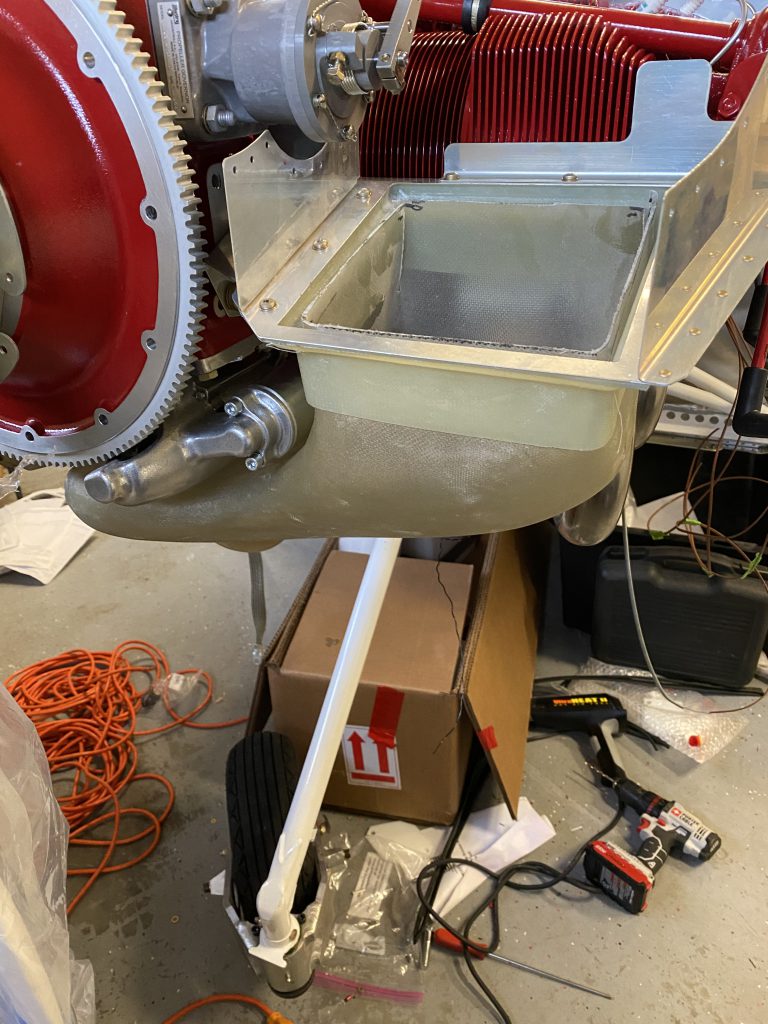

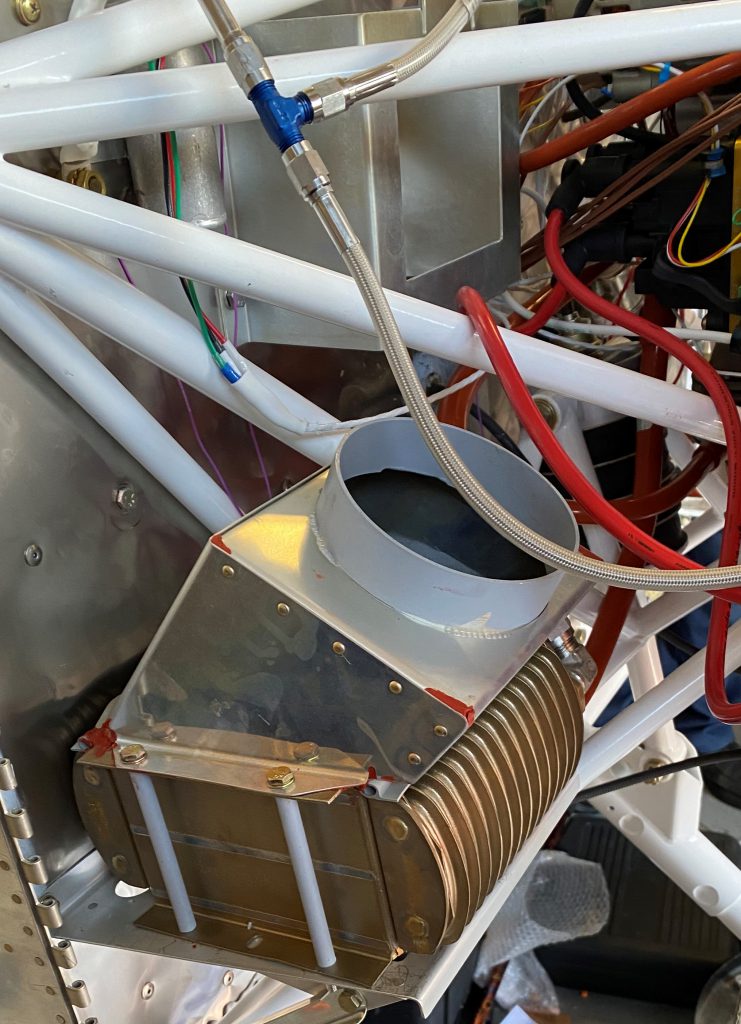

Jim Van Laak stopped by to assist on the engine work. We did the final fit and attachment of the snorkel, attached the mixture and throttle cables, safety wired the propeller and the primary alternator and began working on the cowling.

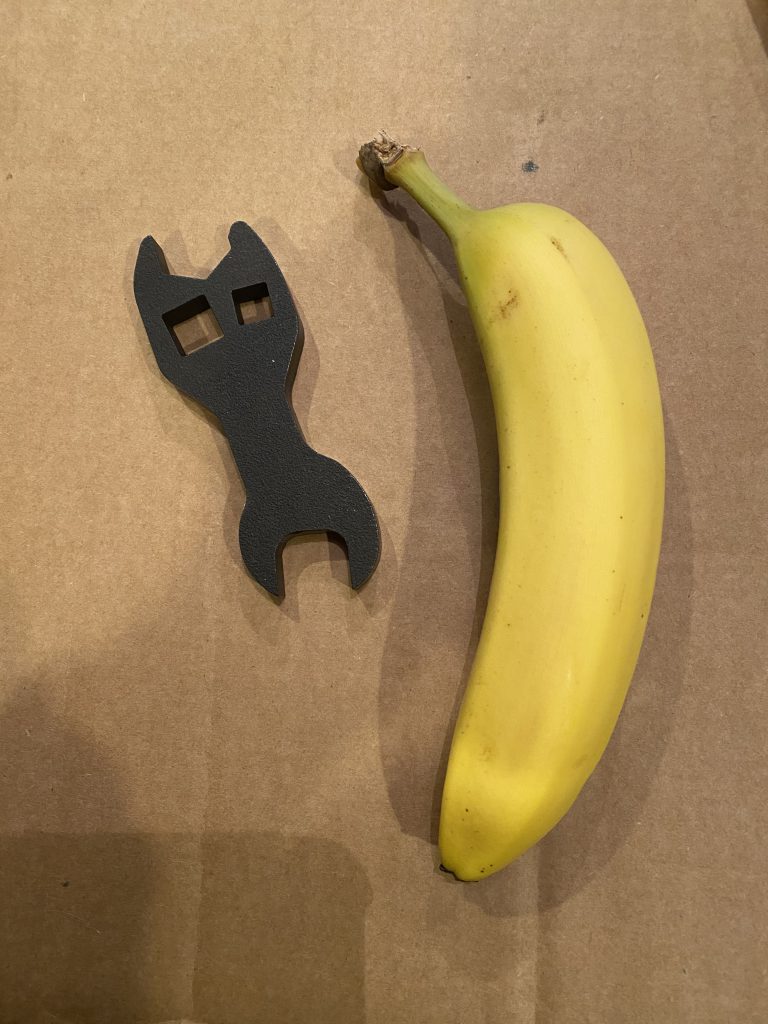

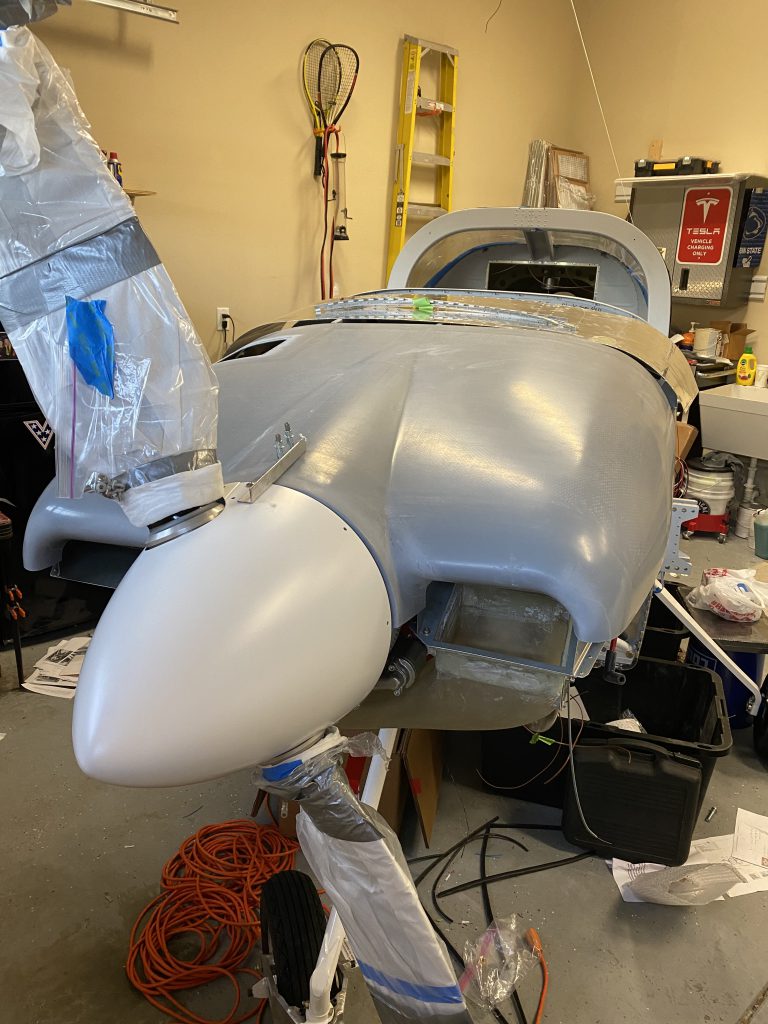

I am using the Skybolt fastener system for the top cowling and using the Van’s hinge system on the firewall side of the lower cowling. I have to say the Skybolt hardware is very nice — their documentation not so much. I am pretty sure I would never have figured it out without Chris Moon and Jim’s assistance. My father and I have nearly completed all the Skybolt fasteners on the aft edge of the top cowling. Still need to adjust each fastener so they lock down flush (easy adjustment).

A few key things I have learned:

- you can’t preinstall the Skybolt receivers into the flanges because you need the hole open to scribe the line up on the inside of the cowling.

- the receivers have a small pin that you remove after you make final adjustments. This pin needs to face away from the firewall for easy access.

My niece, Sarah, graciously helped by climbing into the airplane and installing a couple washers and nuts that I couldn’t get to (my hands are too big).

I am hoping to finish most of the cowling work this week. Then the exhaust system will be the last big thing to work on. Maybe even move the airplane to the hanger on Saturday.

20 hours.