A few days ago when I was assembling the front canopy assembly, I puzzled over one particular drawing. I couldn’t determine confidently whether the canopy skin went on the outside of the stiffener or the inside. Based on the drawing at the beginning of section 38, I decided the stiffener went on the outside. I did several steps and things lined up nicely so I assumed I had it correct. Well, I didn’t.

Today, I got to a step that had me countersink the OUTSIDE of the stiffener to accept the dimpled skin. Now it was clear that the stiffener went inside of the skin. It seems obvious now, but when I did it a few days ago I am pretty sure I had it right. No damage done and only a few minutes to “fix” the issue.

I then spent a fair amount of time looking forward a few pages in the instructions. Geez, this canopy has a lot of steps! I think Jon’s advice to work in small increments of perhaps an hour in the evening makes a lot of sense. It is easy to feel overwelmed if you are working for 8 hours at a time.

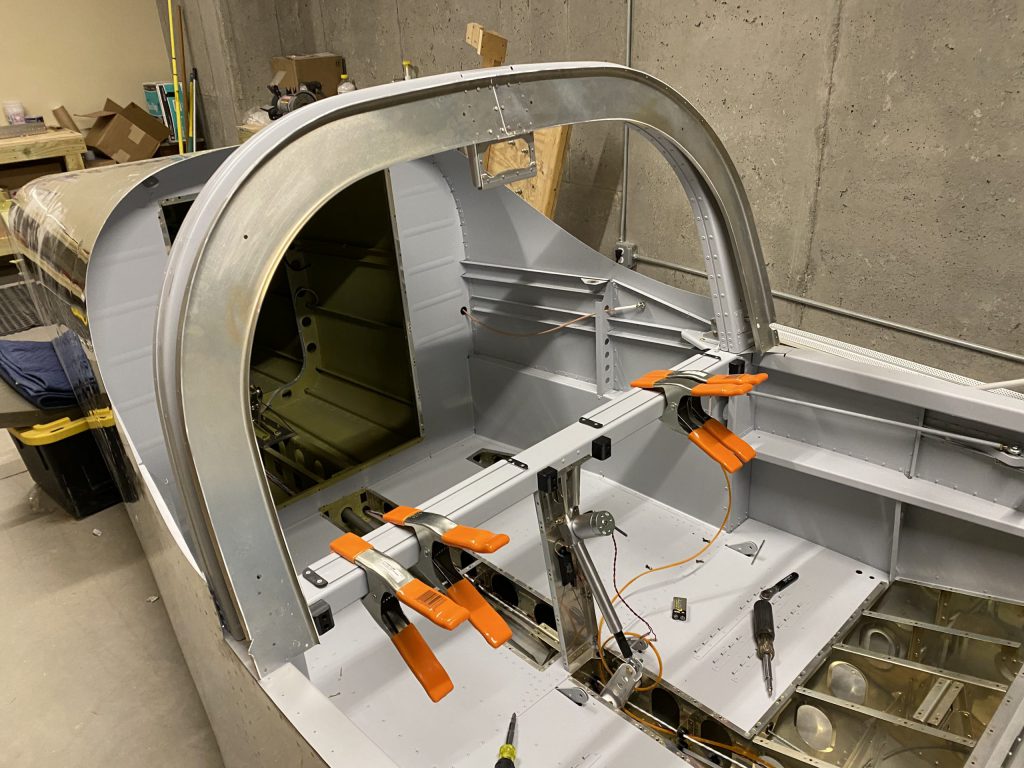

Meanwhile, Steinair seems to be on schedule to finish the panel work by the end of April. Van’s shipped a few more parts that were back ordered in the finish kit. I cleaned the aircraft factory (a little) in an attempt to not work on top of my instructions (which required me to continuously move my work pieces every time I needed to refer to the directions).

Three hours.