Finished painting the canopy frame and other miscellaneous parts. I still don’t completely understand the spray gun and the proper technique. Overall pretty happy with the result though. Probably a solid B for quality. The important thing is that I am no longer blocked from moving forward with the windshield install.

6 hours

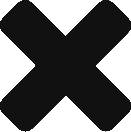

A Great Day for Painting

It took me four tries to build a paint booth that I’m happy with. The key was using heavier (4mil) plastic. I used two exhaust fans and a single inlet vent. I also have a small electric space heater that can quickly raise the temperature in the booth to about the surface temperature of the sun.

Today’s goal is to paint more interior parts and the canopy frame. I need to get the frame painted so I can install the plexiglass windshield and rear window.

The biggest thing I’ve learned about painting is that the set up to paint takes 10x the time it actually takes to paint.

Meanwhile the panel should arrive on Wednesday. Jon thinks it will take a couple weeks to get the panel fully in. He is probably right, but I am hoping it is quicker than that since the engine should be arriving in three weeks or so (and I still have to glue the canopy).

3 hours (not including the drying time)

Some Interior Painting and Misc.

Jon and I painted sone of the access panels. They came out pretty good. Some minor contamination (dust) and the paint needed to be reduced a little more but quite happy with the result.

We also began prepping the rear window for Sikaflex (glue). Jon took measurements for the engine grounding strap.

I ordered the new firewall forward hose package from Aviation Specialty. Steve gave me full credit for the slightly older hoses I bought toward the new ones with integrated fire sleeve. The hoses are beautiful.

The engine looks to be three weeks out and the instrument panel is two weeks away.

Twelve hours (2 people x 6 hours)

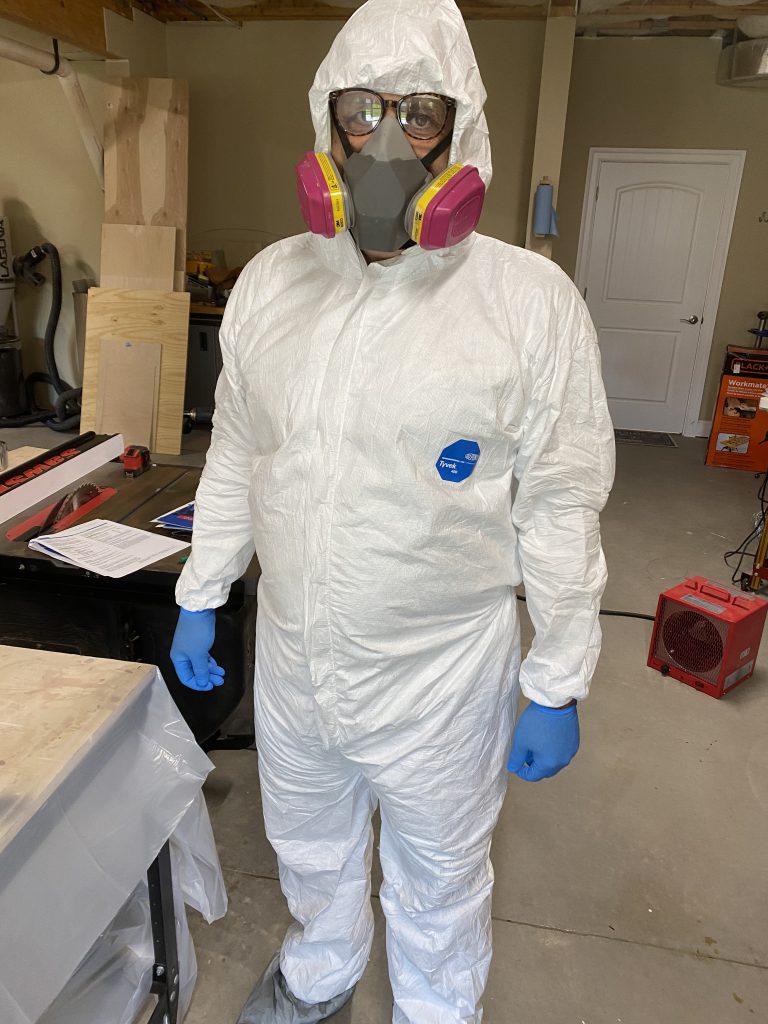

Pictures from SteinAir

Josh at SteinAir sent me pictures of my panel. He is estimating that it will be ready to ship by the last week of April.

Nose Gear Miscellaneous

We worked on the two small offsets that are used to attach the wheel pant to the nose gear fork. The plans call for cutting these from solid blocks of aluminum. Much harder to do than you might think. The bandsaw struggled to cut through the blocks. I probably need to get another band saw blade.

Van’s sent an e-mail asking for the rest of the money for the engine. This means it should be here in the next 30 days. Woo hoo!

2 hours (2 people x 1 hour)

Nose Wheel Pant

Dad and I did some cutting, sanding and fitting on the nose wheel pant last night. It looks pretty good. It’s clear that the instructions were lifted from an older plane design because they have several steps that are largely unnecessary (again thanks to the high quality of the RV-14A kit).

We also did the alumi-prep and alodine processes on several more pieces that we will be using soon.

The paint booth is delayed by a few more days. The fans I ordered on Amazon were supposed to arrive yesterday, but now look like they will get here on Sunday. Not a big deal since we have other small tasks we can work on.

Lycoming says they are starting assembly of the engine. My best guess is that it will be ready to ship by early to mid May.

2 hours (2 people x 1 hour)

Cockpit Stuff

We worked on the flap actuator cover and the center arm rest / map box. I put some of the seat pan panels in place but only used a couple screws to secure them since i will have to remove them to paint.

We put the seat cushions in just to see what they look like (they look good!).

Meanwhile, we built most of the paint booth on the back patio. Still waiting on the fans and filters.

I also spoke to Steinair today. In normal times we would get the panel in about 3 weeks, but of course this is not a normal time (Covid-19) so I am thinking it will be 5 weeks (mid-May). I have several things i can still work on including the canopy and more fairings.

10 hours ( 2 people x 5hours)

More Wheel Pants Work

Continued sanding the two parts on the left wheel pant. I cut the hole for the gear leg and final sanded it. I thought that would be more difficult than it turned out to be. I really can’t do much more on this wheel pant until the airplane is on the gear.

2 hours (2 people x 1 hour)

Busy Work

Kind of bouncing around a bit. Waiting for a part, or the paint booth etc. Today my father and I worked on the wheel pants and did some prep work on the miscellanea section.

I will get the interior paint and primer from Jon tomorrow. My friend Dave (who is an experienced fiberglass and paint guy) is going to help me paint many of the interior parts.

8 hours (2 people x 4 hours).

Engine Mount Installation

My father and I installed the engine mount. Six bolts (three different lengths). Only a small amount of reaming necessary to get the bolts in. Had to search for the AN1149FO632P washers called out for the top two bolts. Had a slight interference issue with one firewall item.

Began fabrication of the main gear leg components.

Two hours (Two people x 1 hour).